DEVELOPMENT AND TRIBOLOGICAL CHARACTERIZATION OF DUAL PARTICLE AND TRIPLE PARTICLE REINFORCED AL-7075/ AL2O3

METAL MATRIX COMPOSITE

Raghavendra N1,V S Ramamurthy

Research Scholar, Department of Mechanical Engineering, B N M Institute of

Technology, Bangalore.1,

Professor and Head, Department of Mechanical Engineering, Yellamma Dasappa

Institute of Technology, Bangalore2

ABSTRACT

The this work the study on hardness and wear behaviour of dual particle and triple particle size Alumina (Al2O3) reinforced aluminium alloy based metal matrix composite (Al2O3-Al MMC) was carried out. Al- MMCs were prepared using 10 vol% Al2O3 reinforcement into aluminium metal matrix and developed using stir casting process. Stir casting is a most suitable process for the production of particulate MMC in which the reinforcement is introduced in to the molten matrix material with simultaneous stirring. The reinforcement in the range of particle size with Dual particle and Triple particle at 10% volume fraction with range from coarse to fine size were used (210μ, 180μ, 80μ & 10μ).The hardness of the composite was determined by Vickers hardness tester and Brinell Hardness Tester. Tensile strength was determined by Universal Testing Machine (UTM). The wear rate was found by pin-on-disc type wear testing machine with steel disc of 60HRC hardness in dry sliding condition. Wear test was conducted on all the samples at speeds of 300,600 and 900 rpm by varying the load (2kg, 4kg, 6kg & 8kg) at a constant sliding distance of 55mm. The wear track studies were carried out by optical microscope .The test results showed that Dual particle composite and triple particle composite exhibited better hardness compared to as cast AL- 7075. Strength of Triple particle reinforced MMC was found to be higher than that of dual particle reinforced composite material. The wear resistance properties of dual particle MMC was higher compared to triple particle reinforced MMC. The secondary process will further enhances the wear resistance of the composite and also that heat treatment will promote the wear resistance.

KEYWORDS

Dual Particle, Triple Particle, Stir Casting Al 7075, Al2O3, Wear rate.

1. INTRODUCTION

Aluminum alloys extensively used by aircraft, automobile and marine applications due to its light weight, Stiffness and strength. The fuel efficiency in automobile, aerospace and marine engines is strongly addressed by high performing components that are fabricated out of Al alloys. Aluminum alloys exists in different series depending on the alloying elements out of which 2xxxx, 6xxxx and 7xxxx are used in automobile and aircraft applications. Aluminum alloys having food response to heat treatment are 6xxx and 7xxxx with higher strength at both as cast and heat treated among all other series. Al-6061 alloy are highly corrosion resistant with moderate strength and finds it application in Automobile engines and valves. Al 7075 alloy are the strongest among all series and further enhancement in strength can be achieved by T6 heat treatment.

Aluminum alloy Al7075 possess very high strength, high toughness and are preferred in

aerospace and automobile sector as compared to AL2024 and Al 6061. The high strength,

hardness, fracture toughness, wear resistance are further enhanced by addition of reinforcements to the Al alloys. The compostes developed in such a combination are most suitable for wear resistant application as compared to alloy and monolithic materials. Also at high temperature applications it is the most suitable material.

The fabrication of the composite material consist of solid and liquid processing which are mainly including techniques such as stir casting, liquid metal infiltration, squeeze casting, spray codeposition, powder metallurgy etc. Powder metallurgy route of MMC production is suitable for critical parts due to its defect free components but adds to the cost of the part. The particulate MMC are developed to a large quantity to reduce the cost of the production and for mass production which can be best achieved by casting route. The uniform distribution of particulate are achieved by stirring the mixture to create the vortex and disperse the particles in the viscous melt. Therefore Stir casting process are suitable for particulate MMC for mass production of structural and wear resistant parts.

2. EXPERIMENT

Composite material development are controlled by the factors related to alloying elements in matrix, Reinforcements size and shape and process parameters. The performance of the composite for specific application are achieved through the controlling all the above parameter at the specified level with the through past experience. The poor performance of the MMC can be reduced by the controlling parameters of matrix, Reinforcements and casting process. Also the compatibility of the matrix and the reinforcements in terms of thermal, chemical and physical parameters are to be taken care in the selection of the material stage.

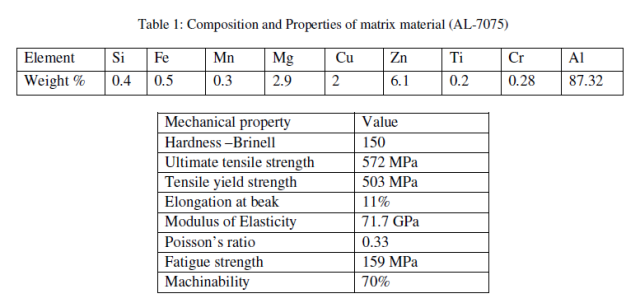

The aluminum alloy Al-7075 was used in the fabrication of MMC in this work. The matrix

material will be stable during melting process with the Alloy and are stable at the melting temperature. The material also has good response to age hardening, heat treatment process and precipitation hardening. The properties of matrix material are shown in Table1.

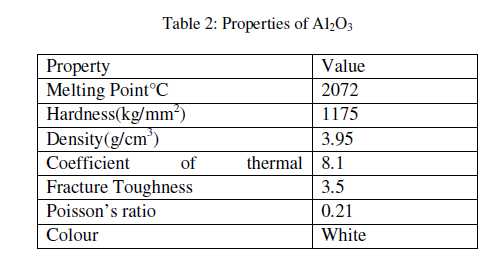

The reinforcement alumina (Al2O3) is in the form of particle size 50 micron to 210 micron are used in the present study. It is more stable with matrix alloy and has high melting temperature. It is an oxide ceramic having low affinity to oxygen to form oxides. The size of the particulate form is such that it has s better distribution in the matrix which produce the isotropic property for the composite. The properties of the alumina are as shown in table 2.

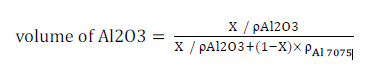

The amount of reinforcement to be dispersed in the matrix medium is selected as 10%. The quantity of reinforcement was calculated on volume fraction basis. To determine the quantity of the reinforcement following mathematical relation was used:

Where,

X = Weight of reinforcement

ρAl2O3 = Density of reinforcement , ρAl7075= Density of matrix

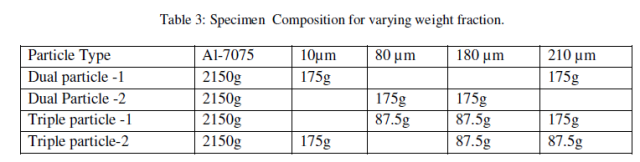

To prepare the dual and triple particle composites, reinforcements had to be selected in various combinations. Table 3 shows the combination of reinforcement particles mixed in the matrix to develop the composites.

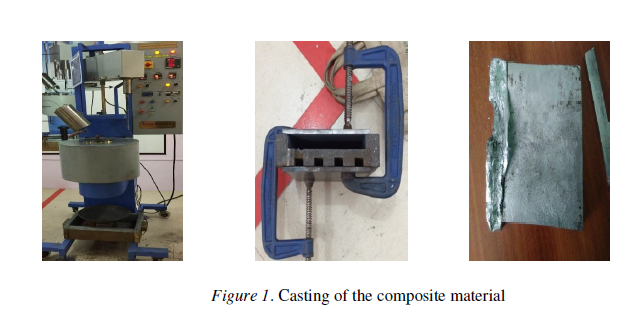

The matrix material Al-7075 was obtained in the form of rectangular billet of 20mm x 10mm area and length 50mm. The alloy are initially cleaned with acetone to remove the impurity, dust and oil and pre heated in the in graphite crucible in electric furnace. The quantity of alumina and the reinforcement are shown in table 3. The furnace temperature was held at 900ᵒC, the melting temperature was carried out at 800ᵒC. The reinforcement was heated separately at 450ᵒC. The stirrer coated with graphite was used for stirring of the melt to have the uniform dispersion of the particles. The slag and other impurities from the melt was removed prior to stirring . The stirring at a speed of 500 rpm with the stirrer blades at half the depth in the melt was used and stirring was carried for 10 minutes. The molten metal with the reinforcements were poured in the

metal mold without drop in the temperature of the melt. The furnace was provided with a bottom pouring arrangements and the mold was kept at the bottom to ensure no settling of the particle in the melt. The stir casting furnace with bottom pouring arrangement and temperature and stirrer rotation control, metal mold used and the casting developed in slab form are shown in figure 1.

Microstructure of the material as determined by any of the available microscopic techniques including reflected light metallography and scanning electron microscope (SEM). The microstructure analysis reveals the distribution of reinforcement in the matrix. Distribution of the reinforcement in the matrix depends on the viscosity and the speed of stirring which decides the final properties of the matrix. The uniform dispersion can be observed in the microstructure analysis.

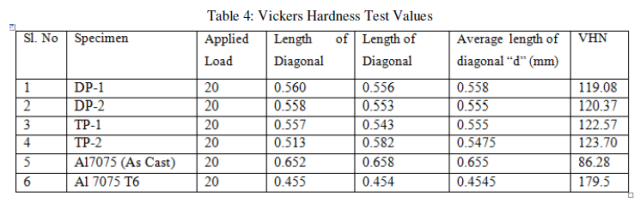

Vickers Hardness Test was conducted according to ASTM E384 standards. Vickers testing is divided into two distinct types of hardness tests: macro indentation and micro indentation tests.These two types of tests are defined by the forces. Micro indentation Vickers (ASTM E 384) is from 1 to 1000 gf and macro indentation ranges with test forces from 1 to 120 kgf as defined in ASTM E 92.

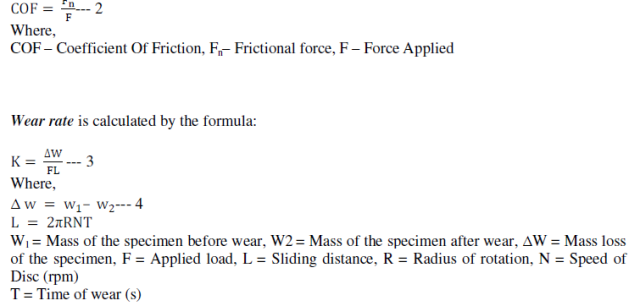

The wear behavior of the MMC was determined by Pin on Disc wear testing machine. The wear rate at the varying disc speed and load on the pin are found. The mass loss was determined and converted to volume loss for the calculation of the wear rate.

The type of wear existing in the current study is adhesive wear which are common in most of the dry sliding applications. The coefficient of friction was also evaluated with the friction force during the testing.

Coefficient of friction is calculated by the formula:

3. RESULTS AND DISCUSSION

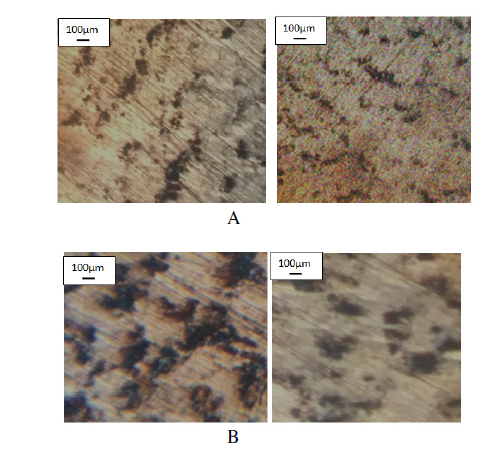

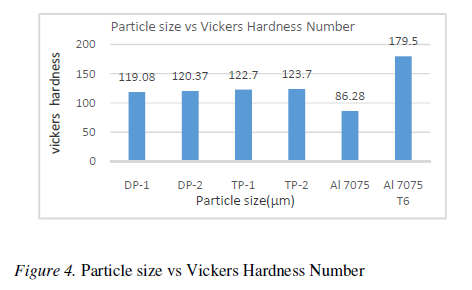

Optical micrograph is shown in the figure 2 which clearly reveals distribution of reinforcement Al2O3 for all the casting under investigation. Dendritic structure can be observed which is due to many factors like thermal conductivity mismatch, melting temperature etc. Stirring action also influence the dendritic growth. The optical micrograph for dual particle reveals more uniform distribution compared to triple particle. Little particle clustering is observed at some places due to imperfect wetting during addition of particles.

The presence of alumina in the Al 7075 affects the dendrite structure. Similar findings are reported by various researchers. The clustering may also be caused by the accumulation of Al2O3 particles in the liquid between the growing dendrites, which seems to inhibit continued dendritic growth.

The micrograph shown in figure 2.a indicates dual particle reinforced composite has uniform distribution of reinforcement than triple particle. Coarse particle produces uniform distribution compared to coarse and fine particle. Overall structure indicates presence of alumina particles in the matrix which leads to better Tribological and mechanical properties of composites.

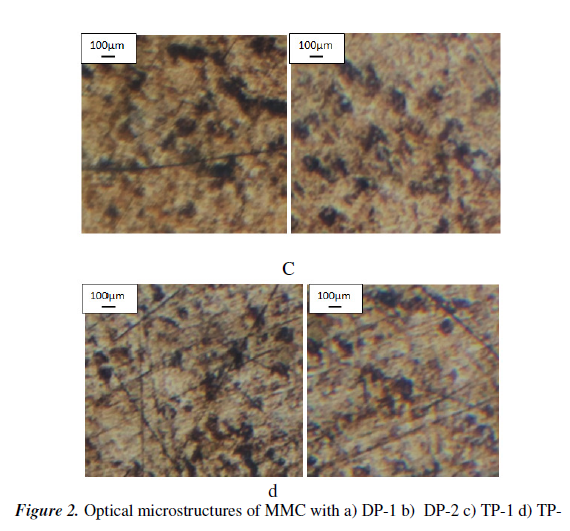

Scanning electron micrograph of composites is shown in the figure 3 indicates the grain boundary and the particulates of reinforcements. The SEM of all the specimens indicates the presence of primary columnar dendritic grains and uniform small grain size due to the use of metal mold. The reinforcement particles are distributed uniformly on grey scale. The particles added externally into the melt remains as it is (Al2O3). The optical micrograph at higher magnification clearly indicates the Al2O3 particulates with fair uniform distribution.

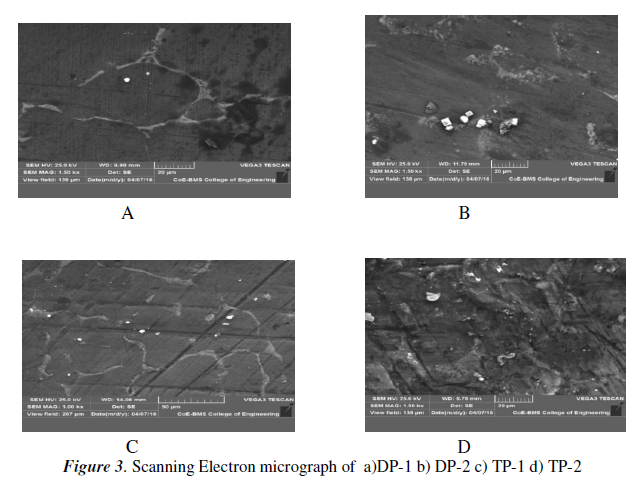

The composite hardness is measured in as cast condition which is lower than hardness of Al 7075-T6 as seen in the figures 4 But when comparing with hardness of as cast 7075 aluminum alloy nearly 30% increase in hardness value can be observed.

Therefore heat treating the composite material will increase the hardness further as compared to Al 7075-T6. Hardness also depends on interfacial boundary between the matrix and the reinforcement. The figure 4 indicates that triple particle reinforced Composite has enhanced hardness due to stronger interface bond and fine particle size.

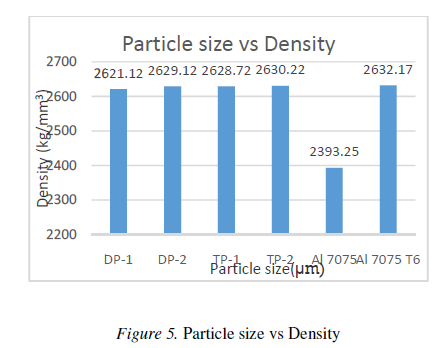

Density of the composite material was calculated by rule of mixture for theoretically and experimentally are as shown in figure 5, the values are close to each other with only 8% porosity. It indicates good casting with no inclusions and air bubbles in the castings. The figure 5 show the range of density as well as the porosity of all the specimens with the as-cast and T6 Al7075.

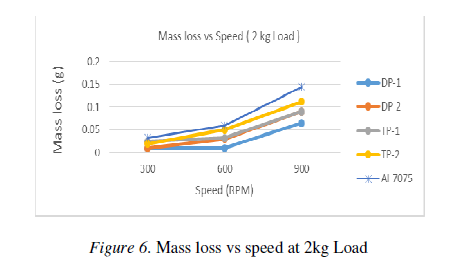

The mass loss (wear) of dual and triple particle reinforced composite as a function of load, measured at different speed at room temperature is indicated in the figure 6. The mass loss increases with the increase in speed of the disc, this behavior is due to the wear of the particle at higher speed or due to the fracture of the particle. It is observed in the figures that wear of the composite increases at room temperature for different speeds.

For Al-7075 the wear rate (mass loss) is higher than the composite material which can be seen in the figure 6. The mass loss obtained for the triple particle composite 1 and 2 was found to be higher than the mass loss of dual particle composite 1 and 2. At higher speeds transition in wear process occurs which is associated with breakdown of tribo layer. Wear process proceeds with removal material with fracture in Reinforcement and matrix due to high frictional force. Increasing in sliding speed results in formation of molten matrix material that adheres to the steel disc.

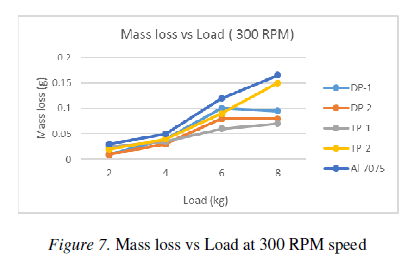

The mass loss (wear) of composite materials as a function of speed, measured at different loads at room temperature is indicated in the figure 7.The wear test shows that the wear (mass loss increases with the increase in load. Graph shows that increase in load leads to increase in mass loss of the composite material. For Al-7075 alloy the wear rate is higher when compared with the composite materials i.e., dual and triple particle composite.

In general, wear resistance is property which depends on the mechanical properties of the composite such as hardness, strength.The presence of different sized Al2O3 particles will alter the wear behavior with increases the particle size wear resistance increases.During composite increases which increases the wear resistance. From graph it can be observed that the dual particle composite material has higher wear resistance than the triple particle composite material.

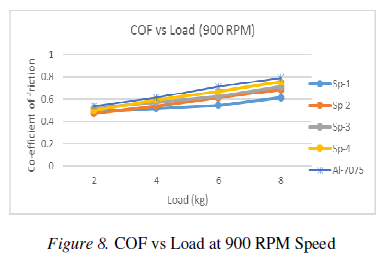

The variation in co-efficient of friction with respect to the change in load is shown in the figure 8.The friction co-efficient of the composite and the aluminum alloy increases with increasing load for all the materials.For the aluminum alloy the friction co-efficient has the higher value compared to the composite material. It can be seen that at the beginning of the sliding motion, the value of the friction co-efficient is lower than that at the end of the motion.

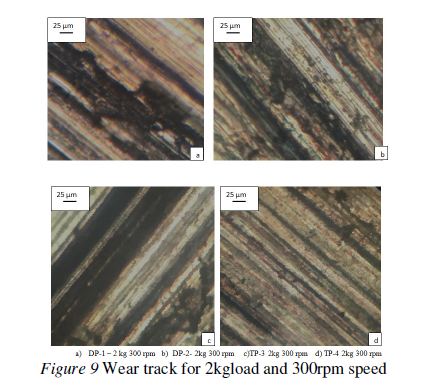

Microstructure study of wear track at different loads and speeds are shown in the following figures. The wear track for 2kg with 300 rpm indicates increase in wear loss as seen from the figure 9. More grooves and wider grooves are formed at higher speed.

Delamination and broken particles are observed with higher loads and higher speed, delamination is more with increase in temperature. More grooves are visible at higher speeds; overall worn surface exhibits combination of abrasion, adhesion and mild oxidation at the varying speed and load.

At highest load rapid surface wear is exhibited and thereafter wear loss is exhibited drastically. The continuous longitudinal grooves parallel to sliding direction on the worn surface of composite are due to ploughing action of particles. The depth and width of micro ploughing increases with increasing load and higher load material is removed mainly due to delamination which results from micro cracks.

4. CONCLUSION

1. Aluminum (Al 7075) and Alumina (Al2O3) particulate metal matrix composites was

developed satisfactorily by Stir casting process with three different particle size addition of reinforcement combined with preheating of particulates.

2. The uniform dispersion of the particulate achieved by creating the vortex by constant

stirring, maintaining the optimum melt temperature.

3. Isotropic property of the MMC was satisfactorily achieved by Stirring the melt and

using the metal mold.

4. The particles are distributed more uniformly in dual particle composite than the triple

particle composite.

5. Al-7075/Al2O3 particulate MMC composites exhibits improved hardness when

compared to the hardness of casted Al-7075 alloy due the hard reinforcements.

6. The wear increased with increase in load. Also the wear in triple particle is found to be

greater than the dual particle.

7. The mass loss found to increase with increase in speed. Also the mass loss in triple

particle is found to be greater than the dual particle.

8. The co-efficient of friction found to increase with increase in load. Also the coefficient

of friction in triple particle is found to be greater than the dual particle.

9. The co-efficient of friction found to increase with increase in speed. Also the coefficient of friction in triple particle is found to be greater than the dual particle.

10. Delamination and broken particles are observed with higher speed and higher load in the wear track analysis

ACKNOWLEDGEMENTS

The author would like to Acknowledge and thank BNM Institute of Technology, Bangalore for support extended to carry out the Project at the research lab at the Mechanical Department.

REFERENCES

[1] H. R. Ezatpour, M.Torabi-Parizi, S. A. Sajjadi, (2011) “ Microstructure and mechanical properties of extruded Al/ Al2O3 composites fabricated by stir-casting process”, Materials Science and Engineering A 528 8765– 8771.

[2] A.Włodarczyk-Fligier, L.A. Dobrzański, M. Kremzer, M. Adamiak,(2008)”Manufacturing of aluminium matrix composite materials reinforced by Al2O3 particle”, Journal of Achievements in Materials and Manufacturing Engineering, volume 27 Issue 1..

[3] S.A Sajjadi, H.R. Ezatpour, H. Beygi,(2012),” Fabrication of A356 composite reinforced with micro and nano Al2O3 particles by a developed compocasting method and study of its properties” , Journal of Alloys and Compounds 511, 226–231.

[4] Serdar Osman Yılmaz, SonerBuytoz,(2007),”Relationship between thermal and sliding wear behaviour of Al6061/ Al2O3 metal matrix composites”, J Mater Sci (2007) 42:4485–4493 , Springer Science+Business Media.

[5] N. Parvin and M. Rahimian ,(2012),” The Characteristics of Alumina Particle Reinforced Pure Al Matrix Composite”, ACTA PHYSICA POLONICA A , No 1 , Vol. 121.

[6] A.Daoud, M.T.AbouEl-Khair, and A.N.Abdel-Azim,(2004),”Effect of Al2O3 particles on the Microstructure and Sliding Wear of 7075 Al Alloy Manufactured by Squeeze Casting Method” , JMEPEG , 13:135-143 , ©ASM International.

[7] Mohsen Hajizamani, Hamidreza Baharvandi ,(2011),” Fabrication and Studying the Mechanical Properties of A356 Alloy Reinforced with Al2O3-10% Vol. ZrO2 Nanoparticles through Stir Casting”, Advances in Materials Physics and Chemistry, 26-30.

[8] WANG Yi-qi, SONG Jung-I, (2011),”Dry sliding wear behaviour of Al2O3 fibre and SiC particle reinforced aluminium based MMCs fabricated by squeeze casting method”, Trans Nonferrous Met. Soc. China 21, 1441-1448.

[9] L.J. Yan(2005),” A methodology for the prediction of standard steady-state wear coefficient in an aluminium-based matrix composite reinforced with alumina particles”, Journal of Materials Processing Technology Volumes 162–163, Pages 139–148.

[10] M.K. Surappa, R.K. Uyyuru, Brusethaug,(2006),” Effect of reinforcement volume fraction and size distribution on the tribological behaviour of Al/Composite /brake pad tribo couple, http://www.elsevier.com/locate/wear , Wear 260, 1248–1255.

[11] EnverAtR ,(1998),” Mechanical properties and wear strengths in aluminium-alumina composites”, Materials and Structures, Vol. 31, pp 418-422.

[12] H. Beygi, S.A. Sajjadi, H.R. Ezatpour,(2011),” Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting “, Materials Science and Engineering A 528 , 8765–8771.

[13] Khairel Rafezi Ahmad ,Shamsul Baharin Jamaludin , LuayBakir Hussain , & ZainalArifin Ahmad ,(2005),” The Influence Of Alumina Particle Size On Sintered Density And Hardness Of Discontinuous Reinforced Aluminum Metal Matrix Composite”, Jurnal Teknologi, 42(A) , 49–57 © Universiti Teknologi Malaysia.

AUTHORS